Is 3D Printing of houses viable?

Is 3D Printing of houses or rather walls viable?

3D Printing of walls or houses? Questions to be asked?

Whenever there is a post regarding 3D printing of homes, we are tagged by friends and colleagues to respond to the advantages of moladi vs 3D Printing.

We therefore want to make it quite clear that this post is published purely to summarise our take on the topic and to have the ability to reference these questions without having to repeat the inherent issues associated with the 3D printing process of houses. All of the numbers used for 3D printing cost purposes are assumed as these cost are not readily available for the purpose of this cost example. We would invite any 3D printing entity to help with the actual numbers to take any guess work out of the cost estimation.

The first 3D printing article was posted in 2017 by moladi:

The development of moladi over the years has been achieved by simply asking and addressing pertinent questions.

A few questions just to get to see the bigger picture of 3D printing and see past the headlines

"A house in 24 hours" or "A house in 3 days" (3 x 8 hour shifts)

Is 3D Printing of houses viable?

Using brick and mortar as an example to build a 54.4 square meter house, as this is the building material referred to as the standard method of construction.

- 11,580 bricks plus 15% waste = 13,300 bricks @ R3,05 each (21 US cents) = R40,565 (USD 2,736) delivered to site.

- Mortar - Lintols - Butterfly ties - DPC - Plaster - R20,500 ($1,383)

- Labour: 1 skilled - 4 labour for 40 days = R46,250 ($3,120)

This equates to R107,312 ($7,240) per top structure (walls plastered both sides).

What is the cost of the printer?

This figure is never mentioned yet it is crucial to the viability of any project.

If the printer cost is $1,000,000 and the printer is used to print every day of the year (200 working days) - then the printer would cost (amortised) would be $5, 000 for 200 houses.

|

| PERI - 3D printer set-up process |

How long to erect the 3D printer? Is A crane required on site?

If the printer needs a day to be dismantled and re-erected on the new foundation, then it would only print 100 houses a year - and the printer cost (amortised) would be $10,000 for 100 houses.

If the printer cost $2,000,000 or $3,000,00 then the amortized cost doubles or trebles to $20,000 or $30,000 per house.

The above price do not include the cost of the pumpable mortar or premixed Lavacrete.

The wall volume would equate to approximately 16 cubic meter of pumpable mortar per house. At a density of 2,000 kg per cubic meter (concrete 2350 kg/m³) each house would require 32,000 kg (32 ton) of dry premix to be shipped to site. That's a lot of shipping cost on top of product cost.

"As the cement is already mixed with the necessary sand and gravel aggregates all moisture has to be driven out of the aggregates prior to that the materials are mixed together and put into the bags. If the moisture is still in the material the process of making and curing of the concrete starts while in the bag. Pre-drying is a costly process and as a consequence these dry mix materials are expensive on a per ton or per m3 basis. For smaller prints, this will usually not be a big issue, but for larger prints and multiple buildings this will be a challenge. On the other hand, the ready-mix dry mix mortars are very easy and convenient to use."

What is the cost of the pumpable mortar mix for 3D printing?

For the purpose of determining a "thumb suck" on the mortar cost, this mix design was published by the University of Stellenbosch in South Africa.

- A cubic meter of sand would cost around R300 ($20.25)

- 579 kg of cement at R100 per 50 kg bag - 11.58 bags - R1158 ($78.10)

- The Fly Ash - Silica Fume - Superplasticizer - VMA - R300 (estimate) ($20.25)

- Polypropylene fibres - R300 kg - 1 kg per cubic meter - R300 ($20.25)

- One cubic meter of mortar could cost R2,058 ($138.80) or R32,928 ($2,221) for the 16 cubic meter required.

- Without running cost (electricity or fuel) nor maintenance cost of the 3D printer

- Excluding the freight charges to deliver the printer to the construction site

- Excluding the freight charges to deliver the Magna material delivery system

- Excluding the cost of the dry mix - premixed - Lavacrete, Heidelberg/Italcementi, Laticrete, Lafarge, Siam Cement etc

- Excluding the freight charges of the dry mix - premixed of 32,000kg per 54 m² (estimated)

- Excluding crane and forklift cost to erect and dismantle the 3D printer

The cost to 3D Print the 54,4 square meter house?

- The amortized cost for the printer per year (100 houses) - R148,261 ($10,000)

- The mortar cost - R32,928 ($2,221)

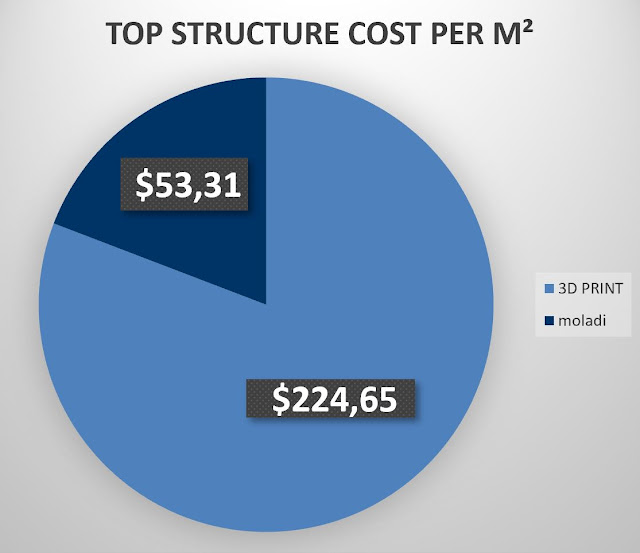

- Total for a 3D printed top structure of 54,4 square meters R181,189 ($12,221)

- Total for a brick built top structure - R61,065 ($4,119) walls plastered both sides - Excluding labour

- Total for a brick built top structure R107,312 ($7,240) per top structure (walls plastered both sides) - Including labour

| |

Cost per square meter floor area - Brick vs 3D printing

Additional equipment required for 3D printer: |

The 3D printing material is very sensitive and needs to be protected from direct sunlight in hot climate areas as water evaporates quicker causing the material to shrink and could result in cracking. The 3D printer also has to be protected from the heat to prevent expansion and contraction. The "tent" structure also prevents the equipment from getting wet during rainy season and the pumped material from collapsing.

The 3D Printed walls are not smooth

The world’s first 3D-printed school is taking shape in Madagascar

Another example of a "Sounds Good Story"

LinkedIn Post:

How many people that think this is a great idea has ever been to Madagascar?

Poverty is a crisis in Madagascar - why would you ship a machine from Finland and incur additional cost to transport the machine/printer to a remote site, when people sit under trees and outside their huts with no jobs? It just is a "sounds good" story.

Take note: on page article #weforum "An artist's rendering of the world's first 3D-printed school is taking shape in Madagascar." Has it been printed? There is a link to donate money...

Natalie Marchant, maybe we can chat? 3D printers require electricity - and most of Madagascar does not have electricity. That means a generator to produce the electricity - and fuel. 3D printers do NOT print foundations. Foundations have to be constructed manually. 3D wall printing can only be done using a graded aggregate to prevent the nozzle from clogging.

3D printers do not print houses or schools - they print only walls. Not foundations - not a roof - not a window - not a door. Walls and finishes that the local community could have built with vernacular materials and "donated funds" - creating employment.

Bamburi parent firm to deliver Kenya’s first 3D-printed home - LafargeHolcim

One of the biggest cost factor that is not mentioned in most of the 3D Print articles is the COST of the printer.

Questions posed to 14 Trees - LafargeHolcim

- What is the cost of the 3D Printer?

- How much did it cost to ship the printer from Malawi to Kenya? $500,000 USD (answered)

- How long does it take to set the 3D printer up before printing starts?

- See the foundation is not 3D printed but trenches dug, reinforcing placed and concrete placed manually by labourers.

- Does the 3D printer gantry need to be bolted to the four columns cast at the corners?

- What is the time span and cost to cast these columns?

- What is the floor area of the finished house?

- What does it cost to produce the walls of the house?

- What is the cost per cubic meter of the pumped material?

- Does the nozzle clog?

The bottom line:

For a $1,000,000 investment moladi would deliver 50 x 54.4 square meter moulds

That means that 50 houses would be delivered in a 2 days (2 x 8 hour shift)

Creating jobs for the unemployed - in order for them to afford buying a home of their own.

Is 3D Printing of houses viable?

Does 3D Printing reduce construction costs?

Tags: moladi, 3D, 3D printing, Cost, viable, cheap, expensive, upfront capital expenses, costing, estimate, building, construction, cost per square meter, 3D-print cost of construction vs moladi construction cost, plasticformwork, formwork