What is the cost to 3D print a house?

What is the cost to 3D print a house?

|

What is the cost to 3D print a house or rather the "walls" of a house? |

What is the cost to 3D print the walls of a house?

Whenever there is a post regarding 3D printing of homes, we are tagged by friends and colleagues to respond to the advantages of moladi vs 3D Printing.

We therefore want to make it quite clear that this post is published purely to summarise our take on the topic and to have the ability to reference these questions and statements without having to repeat what we see as inherent issues associated with the 3D printing process of houses.

All of the numbers used for 3D printing cost purposes are assumed, as these cost are not readily available for the purpose of this cost example. We would invite any 3D printing entity to help with the actual numbers to take any guesswork out of the cost estimation.

First 3D printing post in 2017:

The development of moladi over the years has been achieved by simply asking and addressing pertinent questions.

The questions that need to be addressed by the 3D fraternity are omitted in articles and the people that post do not respond to these pertinent questions. Why?

What is the cost to 3D print a house?

A few questions just to get to see the bigger picture of 3D printing and see past the headlines...

"A house in 24 hours" or " Walls in 24 hours or "A walls in 3 days" (3 x 8 hour shifts)

Is 3D Printing of houses viable?

Using brick and mortar as an example to build a 54.4 square meter house, as this is the building material referred to as the standard method of construction.

- 11,580 bricks plus 15% waste = 13,300 bricks @ R3,05 each (21 US cents) = R40,565 (USD 2,736) delivered to site.

- Mortar - Lintols - Butterfly ties - DPC - Plaster - R20,500 ($1,383)

- Labour: 1 skilled - 4 labour for 40 days = R46,250 ($3,120)

This equates to R107,312 ($7,240) per top structure (walls plastered both sides).

What is the cost of the printer?

This figure is never mentioned yet it is crucial to the viability of any project.

If the printer cost is $1,000,000 and the printer is used to print every day of the year (200 working days) - then the printer would cost (amortised) would be $5, 000 for 200 houses or 100 houses (house every 2 days) or 66 houses (house every 3 days) or 50 houses (house every 4 days)

|

| PERI - 3D printer set-up process |

How long to erect the 3D printer? Is A crane required on site?

If the printer needs a day to be dismantled and re-erected on the new foundation, then it would only print 100 houses a year - and the printer cost (amortised) would be $10,000 for 100 houses.

If the printer cost $2,000,000 or $3,000,00 then the amortized cost doubles or trebles to $20,000 or $30,000 per house.

The above price do not include the cost of the pumpable mortar or premixed Lavacrete.

The wall volume would equate to approximately 16 cubic meter of pumpable mortar per house. At a density of 2,000 kg per cubic meter (concrete 2350 kg/m³) each house would require 32,000 kg (32 ton) of dry premix to be shipped to site. That's a lot of shipping cost on top of product cost.

"As the cement is already mixed with the necessary sand and gravel aggregates all moisture has to be driven out of the aggregates prior to that the materials are mixed together and put into the bags. If the moisture is still in the material the process of making and curing of the concrete starts while in the bag. Pre-drying is a costly process and as a consequence these dry mix materials are expensive on a per ton or per m3 basis. For smaller prints, this will usually not be a big issue, but for larger prints and multiple buildings this will be a challenge. On the other hand, the ready-mix dry mix mortars are very easy and convenient to use."

What is the cost of the pumpable mortar mix for 3D printing?

For the purpose of determining a "thumb suck" on the mortar cost, this mix design was published by the University of Stellenbosch in South Africa.

- A cubic meter of sand would cost around R300 ($20.25)

- 579 kg of cement at R100 per 50 kg bag - 11.58 bags - R1158 ($78.10)

- The Fly Ash - Silica Fume - Superplasticizer - VMA - R300 (estimate) ($20.25)

- Polypropylene fibres @ R300/kg - 1 kg per m³ - R300 ($20.25)

- or is it 2kg per m³ ($40.50) or 3kg per m³ ($60.75)

- One cubic meter of mortar could cost R2,058 ($138.80) or R32,928 ($2,221) for the 16 m³ required.

- Without running cost (electricity or fuel for genset) nor maintenance cost of the 3D printer

- Excluding the freight charges to deliver the printer to the construction site

- Excluding the freight charges to deliver the Magna material delivery system

- Excluding the cost of the dry mix/premixed Lavacrete, Heidelberg/Italcementi, Laticrete, Lafarge, Siam Cement etc

- Excluding the freight charges of the dry mix - premixed of 32,000kg per 54 m² (estimated)

- Excluding crane and forklift cost to erect the 3D printer

- Excluding crane and forklift cost to dismantle and re-erect the 3D printer

Most of the mixtures used for 3DCP today however contain up to 2-3 times the amount of cement of normal concrete mix.

|

| #3DCP - 2 to 3 times more cement than normal dense concrete |

- The amortized cost for the printer per year (100 houses - 2 days per house) - R148,261 ($10,000)

- Or should it be 3 days per house?

- The mortar cost - R32,928 ($2,221)

- Total for a 3D printed top structure of 54,4 square meters R181,189 ($12,221) for a 2 day production cycle

The amount of $12,221 excludes any cost to plaster or rectify any imperfection on the printed wall.

- Total for a brick built top structure - R61,065 ($4,119) walls plastered both sides - Excluding labour cost

- Total for a brick built top structure R107,312 ($7,240) per top structure (walls plastered both sides) - Including labour

|

| Cost per square meter floor area - Brick vs 3D printing The above chart reflects the cost differentiation between brick and mortar and 3D printed top structure. Based on the comparison 3D printing is 70% more expensive than traditional brick and mortar. Bearing in mind that the foundation for a 3D printed structure would require more steel reinforcing and concrete to be able to support the excess weight of the heavier than usual structure. |

Additional equipment required for 3D printer:

The 3D printing material is very sensitive and needs to be protected from direct sunlight in hot climate areas as water evaporates quicker causing the material not to bond and shrinkage could result in cracking. The 3D printer also has to be protected from the heat to prevent expansion and contraction. The "tent" structure also prevents the equipment from getting wet during rainy days and the pumped material from collapsing.

Not everyone is convinced 3D is the answer for the masses.

“Basically, 3D printing is creating a wall system,” said Chris Herbert, the Harvard center’s managing director. “It still has to have a foundation. Someone needs to put on a roof. It’s another way to lower the labor cost of producing components of the house, but it’s not printing every piece of the house.”

“If you can show me how 3D printing can produce components that can be stacked with multiple rooms and dimensions, that would have wider applicability for the overall housing stock,” he added.

Architecture professor Ryan Smith, director of the School of Design and Construction at Washington State University, said he agrees it’s early days for the technology.

“It’s worth investment and work on research in the industry, but I don’t see how it’s going to work in the current supply chain and labor market,” he said. “I personally still feel it will be 30 to 40 years before it will be having an impact.”

|

| The 3D Printed walls are not smooth |

Some additional data from Apis Cor

To demonstrate the potential and the abilities of their mobile construction 3D printer, Apis Cor printed a 410-square-foot house in less than one day. This 3D printed house cost the company approximately $10,150, an incredibly low amount for constructing a home.

Here’s a more detailed list of costs, according to the company’s website:

- Foundation: $277

- Walls: $1,624

- Floor and roof: $2,434

- Wiring: $242

- Windows and doors: $3,548

- Exterior finishing: $831

- Interior finishing (including suspended ceiling): $1,178

- As there is no mention of the cost of the printer nor the amortized cost of the printer we assume that the $275 m² excludes the cost of the printer.

Information obtained from - Link

The world’s first 3D-printed school is taking shape in Madagascar

Another example of a "Sounds Good Story"

LinkedIn Post:

How many people that think this is a great idea has ever been to Madagascar?

Poverty is a crisis in Madagascar - Why would you ship a machine from Finland and incur additional cost to transport the machine/printer to a remote site, when people sit under trees and outside their huts with no jobs? It just is a "sounds good" story.

Take note: A page from a #weforum article "An artist's rendering of the world's first 3D-printed school is taking shape in Madagascar." Has it been printed? There is a link to donate money...

Natalie Marchant, maybe we can chat? 3D printers require electricity - and most of Madagascar does not have electricity. That means a generator to produce the electricity - and fuel. 3D printers do NOT print foundations. Foundations have to be constructed manually. 3D wall printing can only be done using a graded aggregate to prevent the nozzle from clogging.

3D printers do not print houses or schools - they print only walls. Not foundations - not a roof - not a window - not a door. Walls and finishes that the local community could have built with vernacular materials and "donated funds" - creating employment.

Bamburi parent firm to deliver Kenya’s first 3D-printed home - LafargeHolcim

One of the biggest cost factor that is not mentioned in most of the 3D Print articles is the UPFRONT COST of the printer.

Questions posed to 14 Trees - LafargeHolcim

- What is the cost of the 3D Printer?

- How much did it cost to ship the printer from Malawi to Kenya? $500,000 USD (answered)

- How long does it take to set the 3D printer up before printing starts?

- See the foundation is not 3D printed but trenches dug, reinforcing placed and concrete placed manually by labourers.

- Does the 3D printer gantry need to be bolted to the four columns cast at the corners?

- What is the time span and cost to cast these columns?

- What is the floor area of the finished house?

- What does it cost to produce the walls of the house?

- What is the cost per cubic meter of the pumped material?

- Does the nozzle clog?

- What capacity Genset is required?

A second set of questions were posed:

1. It would be great if you can share your calculations as to how you are able to reduce the cost to achieve the "20% cheaper than conventional methods"

2. How will a 70% reduction in CO2 be achieved? Link

"This house printed in 12 hours”: In reality only external walls of a 30 sqm (assumed) structure was printed in 12 hours – No internal walls - No bedrooms - No bathroom - No Kitchen. One door (fire regulations) and 4 windows.

|

| 3D-printed-concrete-house-lafarge |

Did it take 4 months (16 December 2020 - April 2021) to fix the roof, doors, windows and paint the 30 sqm structure?

The cost breakdown of a BRICK & MORTAR House

Foundation - Superstructure - Finishing

|

| BRICK & MORTAR HOUSE |

The minimal impact "IF" a 20% reduction is achieved using a 3D printer on the cost of the house - BUT the massive negative impact it will have on the local community.

|

| 3D PRINTED HOUSE |

To put the numbers into perspective:

What impact will 20% saving on brick & mortar (33% of the value) really have on the total structure - that is "IF" this can be achieved by 3D printing?

A mere 8% reduction or $1447 per house - From $19 172 to $17 724,68 per 54,4 sqm house.

Walls are but one "component" of a house

The big downside of this "20% saving" by 3D Printing the house, is that $3,120 (more than double the "saving" of $1447) will be taken away from the builders, local labourers and community as income to construct the home in brick and mortar - Circular Economy?

So it would seem that the envisaged "20% saving" would simply deprive the local workers and community from earning an income. #SDGs - Poverty?

Here we have "smart" people thinking they can sell a 3D printed house to an unemployed person

A "Holistic Approach"

It is impossible to impact the product "affordable housing" by only changing one aspect of the production process or supply chain It requires a holistic revamp.

Walls are a small percentage of total construction cost of "producing" an affordable house:

Foundation 19% - Super Structure 38% Roof and other finishing 47%

PARODY

"You never change things by fighting the existing reality. To change something, build a new model that makes the existing model obsolete" - Buckminster Fuller -

Video - Erecting the 3D printer before printing can commence

German ready mix mortar cost:

- 1 Ton of 3D mortar mix cost €400 or R6,952.47

- 1 Ton of 3D mortar mix = .42 m³

- 2.38 Ton = 1m³ = €952,71 or R16,547.00

- 1m² of 3D printed wall with no support rib = €95,31 or R1,655 per m²

- 1m² of 3D printed wall with support rib = €143 or R2,482 per m²

|

| 3D printed wall with no internal support rib |

|

| 3D printed wall with internal support rib |

FM inaugurates India’s first 3D printed house at IIT-M - Link

"She expressed hope that with such technology able to deliver a home In five days, the goal of building 100 million homes by 2022, would not be a big challenge when compared to conventional construction."

Yup, a 100 million homes by 2022

220 working days a year @ 5 days per house = 44 houses per year

100 million homes in a year requires 2, 272 727 printers - YUP nearly 2,3 million printers producing at 100% efficiency

The video of the process - A must watch

|

| From morning... |

|

| ... till evening just to erect the wall sections using a crane to shoulder height (1,500 mm?) Not roof height |

|

| Note- No foundation - No floor slab |

Bottom line:

For a $1,000,000 investment moladi would deliver 50 x 54.4 square meter moulds.

That means that 50 houses would be delivered in a 2 day cycle (2 x 8 hour shift)

Creating jobs for the unemployed - In order for them to afford buying a home of their own.

Is 3D Printing of houses cheaper than brick and mortar?

Does 3D Printing reduce construction costs?

|

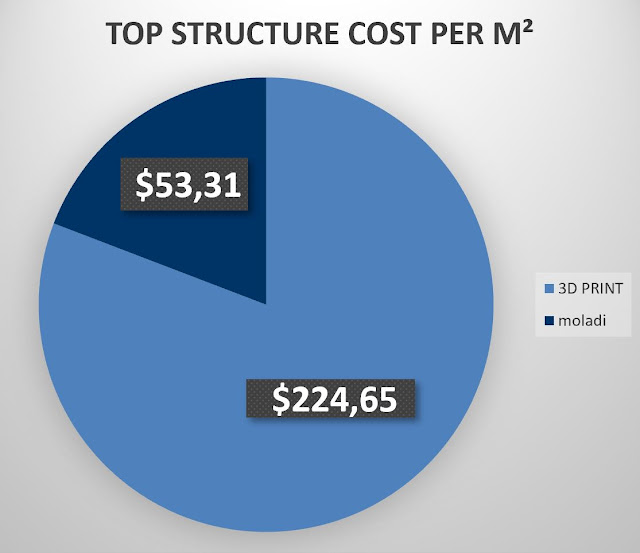

| 3D-print construction cost vs moladi construction The above chart reflects the cost differentiation between moladi and 3D printed top structure. Based on the comparison 3D printing is 325% more expensive than moladi

moladi process - reusable modular formworkFor more information on moladi visit: www.moladi.com |

Tags: moladi, 3D, 3D printing, Cost, viable, cheap, expensive, upfront capital expenses, costing, estimate, building, construction, cost per square meter, 3D-print cost of construction vs moladi construction cost, plasticformwork, formwork, #Holcim #Dr Richard Mukurumbira

Links:

3d printing building construction affordablehousing comparison cost comparison cost effective cost to 3d print a house formwork moladi Is it cheaper to 3D print a house? What is the cost to 3D print a house?

3D house 3D print construction cost 3D printer construction cost How much moladi What is the cost to 3D print a house